Feature

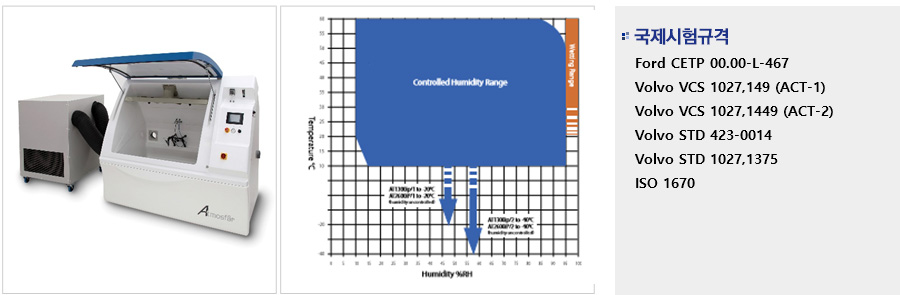

Swing Spray Bar를 통하여 기존보다 높은 재현성 확보 (Volvo 규격)

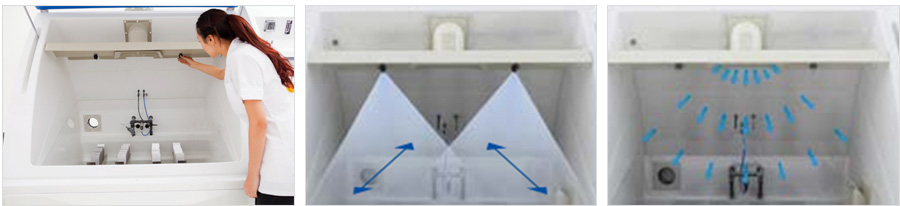

저온모드에서 더욱 강화된 수직기류를 통하여 저온의 균일화 실현

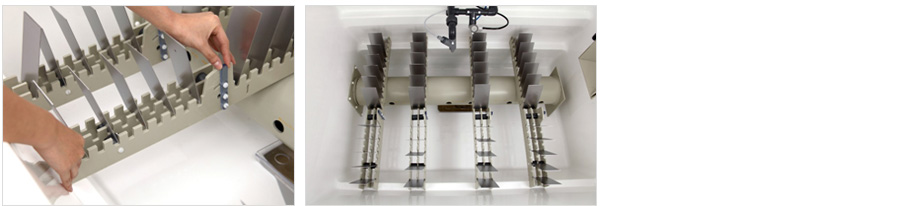

※기존 염수분무 시험이 필요한 경우 손쉽게 제거하여 사용 가능

Adjustable sample racks은 수직에서부터 20°까지의 각도 조절이 가능하고, Sample Rack 단위의 이동이 가능하여 동종의 Sample에 대한 시험분석에 유리하다

Performance

| Wetting mode | Temperature range Humidity range | Adjustable from amblent to +70℃/+158℉ Fixed at 95% - 100% RH |

|---|---|---|

| Oscillating salt spray mode | Temperature range Salt spray fall-out rates |

Adjustable from amblent to +50℃/+122℉ Adjustable from 5 to 10 Ltrs/㎡ per hour |

| Conventional salt spray mode | Temperature range Salt spray fall-out rates |

Adjustable from amblent to +50℃/+122℉ Adjustable from 0.5 to 2.5 ml per 80㎠ per hour |

| Drying mode | Temperature range Humidity range |

Adjustable from amblent to +70℃/+158℉ Uncontrolled |

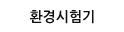

| Climatic mode | Temperature/humidity range | See above graph |

|

|

||||

|---|---|---|---|---|---|

| Atmosfär test chambers | AT1300iP/1 | AT1300iP/2 | AT2600iP/1 | AT2600iP/2 | |

| Minimum controlled temperature | -20°C/-4°F | -40°C/-40°F | -20°C/-4°F | -40°C/-40°F | |

| Chamber capacity | 1300 Ltrs/45.9 cu.ft | 1300 Ltrs/45.9 cu.ft | 2600 Ltrs/91.8 cu.ft | 2600 Ltrs/91.8 cu.ft | |

| Mounting format | Floor standing | Floor standing | Floor standing | Floor standing | |

| Chamber weight (estimated, without optional accessories) |

340kg | 340kg | 440kg | 440kg | |

| Loading threshold | 800mm/31.5" | 800mm/31.5" | 800mm/31.5" | 800mm/31.5" | |

| Chamber external dimensions, max | W D H |

2025mm/80.0" 1316mm/51.8" 1965mm/77.4" |

2025mm/80.0" 1316mm/51.8" 1965mm/77.4" |

2885mm/113.6" 1316mm/51.8" 1965mm/77.4" |

2885mm/113.6" 1316mm/51.8" 1965mm/77.4" |

| Chamber internal dimensions, max | W D H |

1300mm/51.2" 980mm/38.5" 1500mm/59.0" |

1300mm/51.2" 980mm/38.5" 1500mm/59.0" |

2160mm/85.0" 980mm/38.5" 1500mm/59.0" |

2160mm/85.0" 980mm/38.5" 1500mm/59.0" |

| Refrigeration unit Separate unit, one supplied, to be located to the rear or left hand side of the Atmosfär chamber |

W D H |

1510mm/59.4" 1550mm/60.0" 1055mm/41.5" |

1510mm/59.4" 1550mm/60.0" 1055mm/41.5" |

1510mm/59.4" 1550mm/60.0" 1055mm/41.5" |

1510mm/59.4" 1550mm/60.0" 1055mm/41.5" |

| Salt solution reservoir 115 Ltrs/30.4 US gal Separate unit, one supplied to deliver salt water to the conventional salt spray atomizer |

W D H |

560mm/22.0" 620mm/24.5" 675mm/26.6" |

560mm/22.0" 620mm/24.5" 675mm/26.6" |

560mm/22.0" 620mm/24.5" 675mm/26.6" |

560mm/22.0" 620mm/24.5" 675mm/26.6" |

| Salt solution reservoir 160 Ltrs/42.2 US gal Separate unit, one supplied to deliver salt water H 790mm/31.1" 790mm/31.1" 790mm/31.1" 790mm/31.1" to the spray bar |

W D H |

840mm/34.0" 500mm/19.7" 790mm/31.1" |

840mm/34.0" 500mm/19.7" 790mm/31.1" |

840mm/34.0" 500mm/19.7" 790mm/31.1" |

840mm/34.0" 500mm/19.7" 790mm/31.1" |

| Removable slotted sample racks o suit lower rack mounting position |

1 set of 8 racks each with 24 slots |

1 set of 8 racks each with 24 slots |

1 set of 16 racks each with 24 slots |

1 set of 16 racks each with 24 slots |

|

| Each with variable width slots (up to 6mm/0.25") & variable angle (up to 20˚ from vertical) & carrying handle. | |||||

| Chamber construction | Glass reinforced plastic, Polypropylene & PVC parts. | ||||

| Color | 9 standard colors to choose from. | ||||

| Electricity supply | Two 3-phase electrical supplies are required (one for the chamber and one for the separate air conditioning unit). The voltage (VAC) and frequency (Hz) are dependent on country/ region of installation (to be confirmed at the time of ordering). |

||||

| Water | The air saturator, humidity generator and salt solution reservoir all require separate connections to a continuous, pressurized deionized/distilled water supply of 0.5–5.0 bar (7.3–73 psi). |

||||

| Air | Clean dry & oil free compressed air, 4.0 to 6.0 bar (58-87psi) with 240 Ltrs (8.5cu.ft) per minute flow. Two separate supplies are required, one for the chamber and one for the separate salt solution reservoir. |

||||

| Exhaust | 3m (10ft) exhaust pipe is provided which should be terminated outside building. | ||||

| Drain | 3m (10ft) drain pipe provided which should be terminated into floor level drain. | ||||

| Operating environment conditions | Indoors, with ambient maintained at +18 to +23°C (+64 to 73°F), 85% max RH (non-condensing). | ||||