Test Resources specializes in supplying

two types of structural testing systems:

Automotive Test Systems

Automotive Multiaxis Shake Table, Ball Joint Test System, CV Joint Test System, Damper Test Machine,

Elastomer & Engine MountTest System, Shock Absorber, Steering Durability Test System, Tire Testing System

Shake & VibrationTables

3 Axis Earthquake Shake Table Simulator, Horizontal Uniaxial Vibration Table Vertical Vibration Table

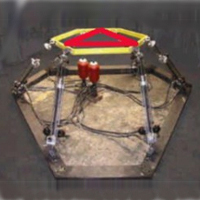

Automotive

Multiaxis Shake Table

TEST APPLICATIONS

Durability testing and performance evaluation of automotive components

Squeak and Rattle tests

Test in strument Panels and seats

Testing fuel tanks, radiators and power train mounting systems

Batteries, supporting structures and exhaust system of LCV

Engine cooling modules test

FEATURES & BENEFITS

Single axis to 6 axis vibration

Frequency 0.01 to 50 Hz

Displacement up to 250 mm(10 inches)

Table size 3m x2m (10 x6.7 foot)

Low friction low maintenance swivels

Powerful digital controller for synchronous multi-axiscontrol and

data acquisitionith power saving 'Green' features.

Ball Joint Test System

TEST APPLICATIONS

Oscillation angle test

Torque test

Rigidity test

Extrusion and drawing strength test

Ball stud static strength test

Fatigue strength test

Service temperature abrasive durability test

Muddy water durability test

Dust cover Ozone deterioration, low temperature and heat resistance test

Optional testing under cold temperatures up to -400C

Optional testing under hot temperatures up to 2000C

FEATURES & BENEFITS

Two 50 kN(11,250 lbf), ±150 mm(6 in) linear actuatiors

5,000 Nm(44,250 lbf·in) servohydraulic rotary actuator

Suitable for static and dynamic testing

2360 digital controller for synchronous multi-axis control and data acquisition

"Green" highly efficient hydraulic power pack

Optional envrionment alchambers and muddy water system

CV Joint Test System

TEST APPLICATIONS

Articulation torque test to measure the torque required to rotate

the shaft, when articulated at any point between 0 to 50 degrees

Measures backlash of the joint, maximum articulation angle,

maximum articulation angle and force at any articulation angle from 50 degrees

Optional testing under coldt emperatures to -400 C and under hot temperatures to 2000 C

Radial expansion measurement

FEATURES & BENEFITS

Hydraulic torque actuator

Torque cell

Suitable for static and dynamic testing

"Green" highly efficient hydraulic power pack

2360 controller for synchronous control and data acquisition

Optional environmental chambers for varying specimen lengths

Damper Test System

The Alternate Torque Rotational test bench applies a servo-

controlled alternate torque to a clutch disk or fly wheel

damper while the specimen is rotating at speeds that can

vary from zero to 6,000 RPM. The torsional system can apply

torque of ±1000 Nm. It can deliver ±1°at speeds up to 60 Hz,

while the component is rotating.

Elastomer & Engine Mount Test System

TEST APPLICATIONS

Static & dynamic testing of elastomers

Determination of loaded height

Determination of static stiffness & dynamic rate

Determination of damping coefficient

Determination of tan delta / phase angle

Durability testing

Part qualification against prescribed tolerances

Statistical analysis

FEATURES & BENEFITS

Fully integrated single footprint system

Interchangeable tooling to accommodate wide variety of dampers

Multifunction operator controls to enable part selection

Air conditioned enclosure for controls, electronics and computer

Fully digital control using 2360 and 2370 series controllers

Actuator stroke options from 25 mm to 100 mm(1 in. to 4 in.)

Frequency: 0.01 to 100 Hz

Optional 200 Hz actuator

Shock Absorber, Damper Test Machine

FEATURES & BENEFITS

Pneumatic tooling with full 3-degree rotational freedom at both ends for self-

alignment

Quick change jaw faces and spacers to switch between parts

Low-force "bull-dog" top grip that will retain top end without damage while resisting

applied tensile and compressive damping force

Top and bottom end tooling to suit threaded and eye type mounts as well as custom

bottom tooling to suit variety of struts and front forks

Configurations available from 8 kN to 25 kN(1,800 lbfto5,625 lbf) dynamic rating

and from 0.005 m/s to 3.5 m/s velocity rating

Tooling suitable for 2, 3 and 4-wheeler parts

Proprietary low noise, servo-controlled pump for energy efficiency(30% of most

conventional pumps)

Compact single foot print packaging with fully integrated system. Simply connect

power mains and compressed air to operate system. Ease of relocation on shop floor

Asynchronous dual-station operation doubles productivity and provides ready cross

reference on test results

Optional sensors to detect complete seal insertion and to detect unseale dparts

Optional sensors to detect part presence and part removal to avoid duplicate test

Steering Durabilty Test System

TEST APPLICATIONS

rack-pull

pinion torque

computation of mechanical frequency

rolling torque measurement

valve curvemeasurement

buckle bending measurement

friction measurement

measurement steering gear stiffness

FEATURES & BENEFITS

30 kN lateral force

200 Nm maximum steering torque

12 month warranty and customer support services.

Meets or exceeds national and international

accuracy standards for materials testing systems.

Tire Testing System

TEST APPLICATIONS

Durability test, Performance evaluation test,

Measurement of dynamic growth of rotating tire as per ECE R75, Radial load test

FEATURES & BENEFITS

Load range to 100 kN(22,500 lbf), Carriages on linear motion guides,

Dual carriage capability, 2360 computerized digital controller with

synchronous multi axis control and data acquisition, "Green" highly efficient hydraulic power pack

Optional laser based optical system for measuring dynamic growth of the tire

3 Axis Earthquake Shake Table Simulator

Our 3 Axis Shake Table or most commonly known as Earthquake

Simulator is used for evaluating specimen response under conditions

that closely simulates actual earthquakes. The specimen are most likely

are buildings, bridges and other civil engineering structures.

Horizontal Uniaxial Vibration Table

FEATURES & BENEFITS

Tables available in 0.5 x 0.5 m, 1 x 1 m, 2.5 x 2.5 mand 3 x 3 m

Linear bearing table mounts

Threaded mounting holes on the table top for specimen

Fatigue rated actuator

Natural frequency exceeds 100 Hz

User friendly software

Full digital control

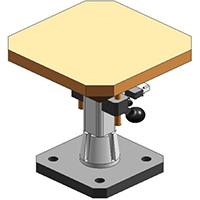

Vertical Vibration Table

FEATURES & BENEFITS

Table rated for 275 kg payload capacity

Table designed for natural frequency in excess of 100 Hz

Table delivers vertical axis movement along one axis (Z-axis)

Vertical movement provided by means of a 50 kN dynamic rated double

ended, double acting pedestal mount servo-hydraulic actuator

Actuator is designed for low stick-slipeffect, with adequate side load

carrying capacity with assured sine wave quality.

Concentric and internally mounted LVDT for displacement measurement

On board hydraulic manifold with 100 L/min direct drive servovalve

MEMS accelerometers(2) rated for 35g, 100 Hz

Hydraulic Power Supply, Controller and Software